What is Chemical earthing

Chemical Earthing Electrode

Table of content

- Introduction to Chemical Earthing

- Earthing Design

- What are the three types of earthing

- Chemical used in earthing

- Which Material is best for earthing

- Which Type of earthing is more efficient

- Types of earthing systems as per IEC 60364

- Method to reduce electrode resistance

- Safeone earthing rod CPRI tested up to 35KA

- Types of chemical earthing

- GI Earthing rod

- Pipe in Pipe Earthing rod

- Pure copper earthing rod

- Solid Earthing rods

- Copper Bonded Earthing rod

- Price of chemical earthing

- Application

- How to install chemical earthing rods

- Testing of Earthing

- Drawing and additional information for chemical earthing

- Chemical and conventional earthing comparison

Introduction to Chemical Earthing

- Chemical Earthing rods are used for electrical systems in earthing applications.

- In this earthing ground enhancement compound is used while the conventional earthing uses salt and charcoal.

- Ground enhancement compounds are excellent conductive compounds.

- It is a mixture of bentonite graphite and Carbon compounds also called chemical earthing compound or backfill compound (BFC). that are mixed with water forming a paste which is poured in the earth pits.

- These compounds surround the electrode as if it were surrounded by metal increasing the ground rod's surface area and decreasing ground resistance.

- Ground enhancement compounds are widely used for poor soil conductivity in Rocks and mountain areas.

- This compound is highly conductive, which reduces the resistivity of ground and helps in quick discharge of fault current.

- Chemical earthing rods are maintenance-free earthing which does not require any water during the complete life span of earthing rod.

- This earthing has a long life as compared to conventional earthing and is very easy to install.

- The ohmic value is retained that is not changed throughout its useful life

Earthing Design

- The best protection for the system should be provided by earthing systems that are designed to ensure proper earthing in accordance with standards.

- This depends on proper selection of earthing rod such as diameter and length of rod and number of earthing electrodes installed.

- Soil resistivity test can also be performed for proper design of earth rods this test also helped for finding resistivity of soil in ohm-meter

- The number of earthing rods depends upon the electrical load short circuit,fault current of the system and soil resistivity of the ground.

- Soil resistivity of ground depends upon moisture content and temperature of ground

- Earthing design calculation is done as per standards below

- IS 3043

- IEC standard IEC 60364 and BS 7430

- Design Parameters & Formula IS-3043

- As per 10.3 of IS: 3043, the current density permissible at the earth electrode is given by.

- Id = 7.57*10³/√(ρ*t) Amps/m²

- ρ – resistivity soil

- t – fault clearance time

- Resistance in ohms of the plate type electrode is given by,

- R = ρ/4 * (π/A) Ω.

- Were,

- A – total area of the earth electrode.

- The Fault current which occurs in the electrical system must be discharged to the earth safely and quickly to avoid electric shock.

- Chemical earthing electrodes have a very low resistance to earth and can discharge the fault current very quickly in a short time.

- Made with excellent quality of mild Steel material and coated 100-250 microns with zinc or copper.

- This earthing rod is filled with backfill compound inside the pipe for reducing the resistance of the rod.

What are the three types of earthing

- Pipe earthing

- Plate earthing

- Solid Rod earthing

Chemical used in earthing

- There are numerous available mixture used in chemical earthing this are carbon based or bentonite based with a mixture of graphite and other compounds

- Conductive cement is also present in some compounds. after installation, it hardens in to a concrete tha does not mix with the ground and is not washed out.

Which Material is best for earthing

- Copper is the material of choice for grounding, but is not often used due to its high cost.

- Stainless steel rods are also used for earthing purpose

- Mild steel which is galvanized and most cost effective used in earthing systems.

- Copper bonded earthing's are most commonly used and are a good replacement of pure copper earthing electrodes. They are most commonly used in replacement of pure copper

Which Type of earthing is more efficient

- Copper bonded strip in pipe earthing rod Commonly used in buildings, factories, CNC and printing machines,

- A copper bonded strip in the pipe of larger-diameter and pipe 3m long ought to have a voltage between neutral and ground less than 3V for optimal performance, due to their low resistance.

Types of earthing systems as per IEC 60364

- IT System- unearthed Neutral system

- TT System-Directly earthed neutral system

- TN System- Directly earthed neutral system with a direct connection between the exposed conductive parts and the neutral

Method to reduce electrode resistance.

- Increasing the surface area of the rod by length and diameter

- To be Deeply driven inside the ground up to 3 meters or above have a great impact in reducing the resistivity of ground for better result.

- interconnection between 2 or more rods gives lower resistance.

- Soil treatment to be done by using high Quality backfill compound.

- Resistance is normally determined by soil conditions, which must be improved through proper design.

CPRI tested Safeone earthing rods up to 35KA.

- GI strip in pipe earthing electrode with a diameter of 76mm was tested for 35KA RMS 1 second and 70KA Peak.

- GI strip in pipe earthing electrode 48mm diameter tested for 20KA RMS 1 second and 44KA Peak.

- Copper bonded strip in pipe electrode 48mm diameter tested for 25KA RMS 1 second and 50KA Peak.

Types of chemical earthing

- GI earthing rod

- Strip in pipe earthing rod

- Pipe in Pipe earthing rod

- Pure copper earthing rod

- Copper bonded Solid earthing rod

- Copper bonded earthing rod

GI Earthing rod

- Galvanized iron earthing rods (GI) are zinc coated that helps to prevent corrosion.GI earthing rods are most economical and widely used.

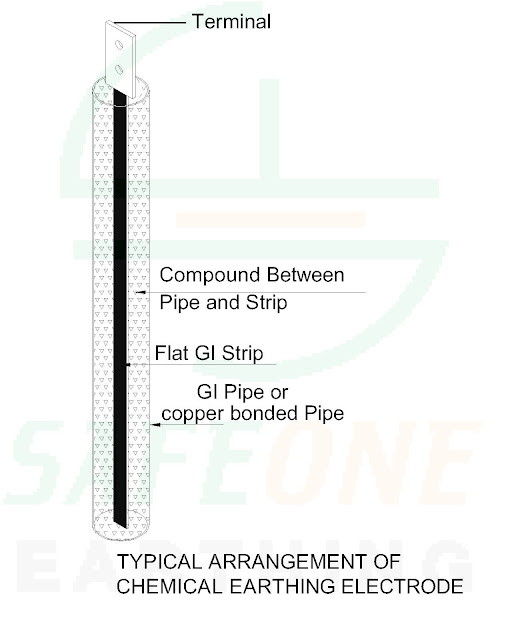

- Strip in pipe earthing rods are electrodes having pipe and strip GI strip inserted inside the pipe at the top of the strip terminal are welded to which earthing strip is connected.

Pipe in Pipe Earthing rod

- Pipe in pipe earthing rods have an inner pipe surrounded by an external pipe.

- These rods are very robust in construction Dual pipe increases the surface area of the rod capable of withstanding heavy short circuit current.

- The inner pipe is covered by the outer pipe and is not exposed to the outside soil or in direct contact, so it will not rust.

- Filled with conductive compound between pipes to withstand heavy short circuit current.

- Can be customized as per requirement..

- Sizes available 50mm and 80mm length 1/2/3 metre

Pure copper earthing rod.

- Pure copper earthing rods are available in solid electrode or plate type.

- They are much more costly then GI or copper bonded rods mostly used in high corrosive environments.

- These rods are lifetime once installed properly.

Solid Earthing rod

- Solid earthing rod is light in weight and easy to install V clamp or T clamp welded on top for earthing strip connections.

- The V clamp has 4 holes and the T clamp has 2 holes on both sides of the clamp for strip connections.

- Copper coated on MS material up to 100 to 250 microns

- Solid earthing rods can be driven deeply by using a coupler up to 3-6-9 mtr or deeper using a coupler on both ends of the rod.

- This earthing can be customized as per the requirement

- Sizes available 14.2/17.2/25/32mm length 1/2/3 metre.

Copper Bonded Earthing rods

- Copper bonded earthing rods are coated with a copper layer. that increases the conductivity and the life of earthing, it also increases the current carrying capacity of fault current.

- Sizes available 50mm and 80mm length 1/2/3 metre

- Copper plating with thickness of 100 to 250 microns.

Price of chemical earthing

- Depends upon length and diameter of electrode most commonly used and minimum price of GI earthing electrode for Diameter 50 mm length 2 mtr electrode will be around 1000 to 1200/-Rs copper bonded same size 1200-1400/-Rs.

- Prices also depend on minimum order quantity to maximum order quantity.

- Advantages of chemical earthing as compared to conventional earthing.

- Easy to install.

- More safety

- Maintenance free.

- No water required

- Good conductivity

- Less space required.

- Low resistance.

- Long life

- Withstand heavy fault current.

Application

- Panel room.

- Meter room.

- CNC machine.

- Transformers.

- Electrical equipment.

- Residential buildings.

- Commercial buildings.

- Lightning Arrester.

- Factories.

- Warehouses.

- Electric Power Distribution System.

- Over head lines

- Substation.

- DG SET

- Telephone Tower.

- Railways

- Power lines

- IT server.

- Rooftop Solar.

- Data center

How to install chemical earthing rods.

- A boring machine is used to install chemical earthing, and a tripod is used for drilling.

- A hole of diameter 100-125mm is to be done by the machine, length of bore below the ground should be done according to the rod length After the drilling has been done earthing rod is inserted inside the bore.

- After the earthing rod is installed, it is backfilled with earth enhancement compound along with water forming a paste and poured into the bore hole.

- This mixture is poured into the bore until the space between the rod and bore area is filled with compound.

- Manual installation can be done if the length of rod is 2mtr or less.

Testing of Earthing.

- Testing for earthing rod is done using earth resistance tester. 3 point testing method are most commonly used

- Rod P1,E2,P2 has to be driven inside the ground with the same distance between them along with the installed or existing rod to be tested. earthing has a good path for flow of heavy current and less resistance to the ground in case of fault current Which protects the system from breakdown.

View complete detail drawing for chemical earthing.

Chemical and conventional earthing comparison Chemical earthing

| Chemical earthing | Conventional earthing |

| Less space required | More space required |

| Easy to install with less manpower | Installation required more manpower |

| Long life 12-15 years | Life 6-7 years |

| Backfill compound such as graphite, bentonite used to reduce the resistivity of ground | Salt and charcoal used to reduce the resistivity of ground |

| The earth enhancing compound has no corrosion effect on earthing rod during complete life span | Salt used will have corrosion effect on rod during the period of time |

| Can be driven deeply to ground with jointing coupler 6 to 9 metre or above | Can be installed not more than 3 mtr |

| Low earth resistivity of rod is maintained for complete life span |